ANAVIA’s brand-new HT-100 UAV takes to the sky with Siriotek Engineering

15 February 2021

ANAVIA AG, based in Switzerland, is the latest player to join the commercial Unmanned Aerial Vehicles (UAV) market, which is forecasted to grow globally above USD 15bn by 2026 fuelled by widespread adoption across Logistics, Surveillance, Agriculture and Emergency Management.

Part of the Connova Group, a global leader in the development of fibre reinforced composites for the Aerospace industry, ANAVIA was established in 2019 with a mission to design, manufacture and commercialise the most advanced UAVs on the market.

From initial concept to final production, the HT-100 has been developed to deliver exceptional performance while combining unprecedented levels of operational flexibility and reliability for mission critical applications together with low maintenance costs. The ambitious scale of the engineering challenge required a creative yet rigorous approach, with innovative design solutions validated and optimised using advanced analysis methodologies and eventually implemented through state-of-the-art technology and manufacturing.

Siriotek was selected by Connova at the start of the project as the key engineering partner for the HT-100 programme, with the ultimate objective of delivering on industry leading technical specifications while meeting the required certification standards within tight timescales.

Working in close collaboration with the ANAVIA design and test teams based in Villmergen Siriotek engineers left no stones unturned in the quest for efficient and reliable performance, with analysis and simulation data driving every stage of the design process across a number of areas.

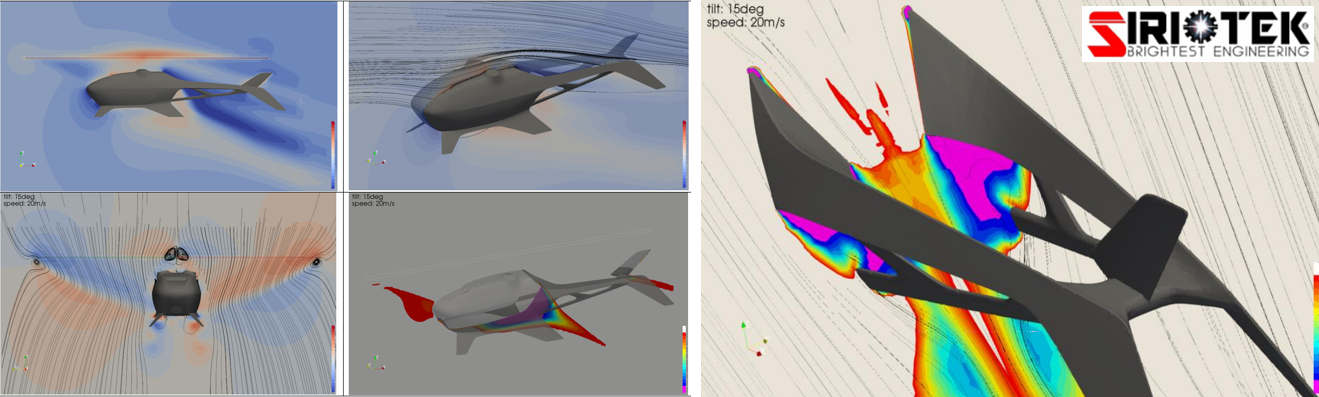

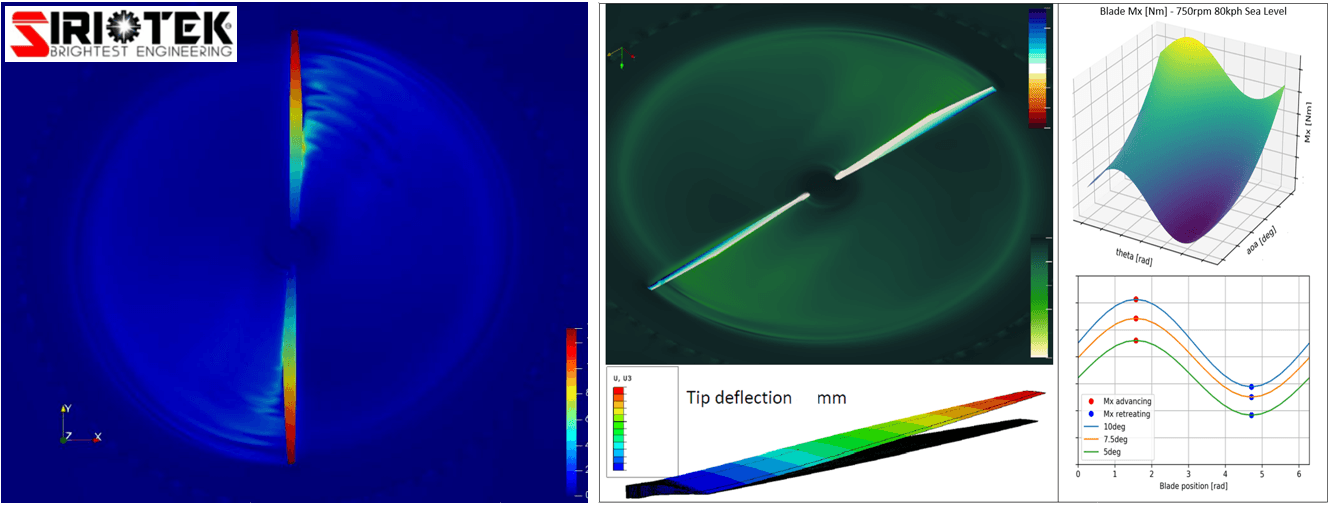

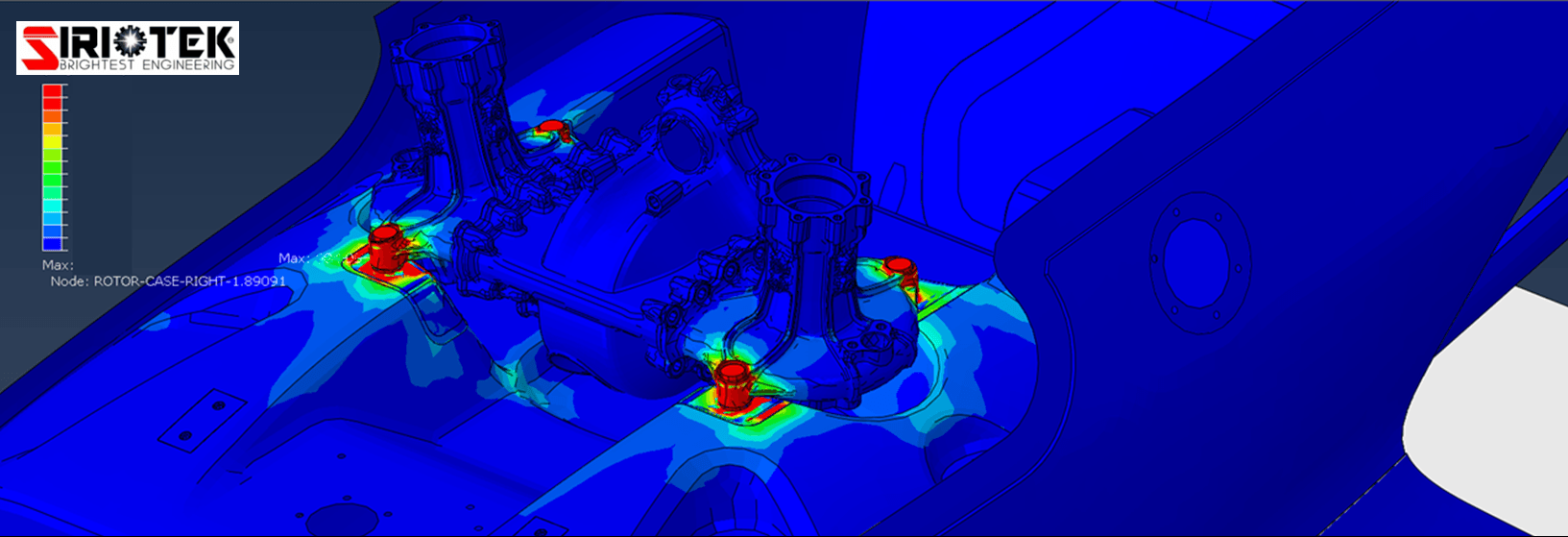

The HT-100 is a twin rotor helicopter with intermeshing blades powered by a 15kW turbine engine. The design process has been driven by detailed and systematic engineering investigations based on Siriotek extensive wealth of experience across Formula 1 and Aerospace:

- The rotor blade profile has been developed to deliver the target lift at different Angle of Attacks with maximum efficiency

- Efficient structural sizing of rotating parts has been achieved with rotor dynamics investigations based on coupled FEA-CFD

- CFD of the airframe has allowed scrutiny and control of blade downwash effects

- The rotor blade carbon fibre laminate has been optimised to achieve target strength with minimum weight, achieving excellent correlation with rig test results

- Calibration of the blade damper element has been supported by nonlinear FEA

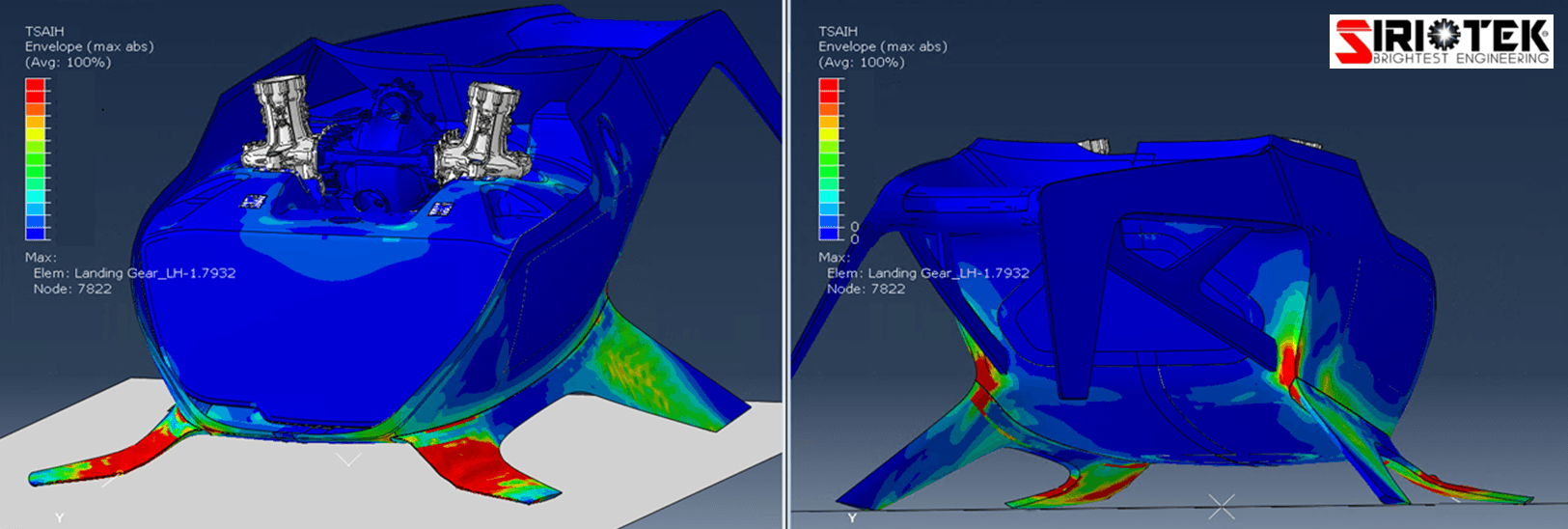

- Airframe and landing gear have been developed to promote the least damaging failure mode in case of crash landing

Every detail has been specifically designed with performance and operational efficiency in mind, resulting in class leading features which make the HT-100 a sensible and more economical alternative to conventional helicopters:

o 4h airborne time with up to 65kg payload capacity and 400km (216nm) rangeo Fully autonomous navigation mode with max speed of 65kn and service ceiling at 10'000ft.o Back-up emergency motor with smart redundancy systemso Intuitive controls with easy mission programmingo Rapid launch readiness and operational capability in adverse weather conditionso High compatibility with mainstream payload systems for a wide range of applicationso Low maintenance costo Certification by the Swiss Federal Office of Civil Aviation

commercial product and its mission is to establish our reputation as a world-class UAV manufacturer.

Meeting the ambitious targets was key to the success of the project and partnering with Siriotek fully

delivered on our expectations both on the technical and collaborative side”

Giovanni Di Lorenzo (CEO – Siriotek): “At Siriotek we love technical challenges and the HT-100 is

among the most exciting projects we have contributed to. ANAVIA totally shares our commitment to

innovation and continuous improvement and we are proud to contribute to their first commercial

product”

ANAVIA AG

With the HT-100 ANAVIA has developed what is arguably the most advanced commercial UAV system in the world, setting new benchmarks in safety, performance and ease of operation. ANAVIA AG is based in Villmergen (Switzerland) and operates as a business unit of the CONNOVA Group, a leading global developer and manufacturer of high-tech carbon composite products for the aerospace industry and motor racing sector.

https://anavia.eu/en/

SIRIOTEK

At Siriotek we blend passion and creativity with specialist engineering knowledge to help innovative Companies deliver on their most ambitious projects. We have a track record of providing practical and efficient solutions to complex problems in product and technology development across diverse industries and take pride on customer satisfaction.

As part of ongoing collaborative efforts focusing on development and optimisation of production technologies for nonwovens, Fraunhofer ITWM and Siriotek have completed feasibility investigations on bematic® latest airlay design “AioLos”. Results are very encouraging and bematic have now committed fully to the new design by confirming manufacturing of a full scale unit, with procurement of parts currently in progress.

Nonwoven fabrics play today a central role in a number of industries, including automotive, healthcare, medical, construction, and filtration. As demand for these versatile materials continues to grow, Bettarini&Serafini S.r.l (trading as bematic®), Siriotek GmbH and the Fraunhofer Institute for Industrial Mathematics ITWM are now joining forces to enhance and develop air-lay technology for production of nonwovens. The joint project will be presented for the first time at ITMA 2023, the trade fair for textiles technology, materials and innovation.